Grease Trap Perth help prevent FOG (Fats, Oils & Grease) waste from entering the public sewer system and causing blockages. They can be found in a variety of establishments and come in a range of sizes.

These devices can be located indoors or outdoors and are distinguished by their manhole covers and septic tank-like designs. Larger grease traps will need professional assistance to be cleaned, while smaller ones can be easily cleaned by authorised restaurant staff.

A grease trap is a receptacle that kitchen wastewater flows through before it reaches the sewer waste system. This receptacle — technically called a grease interceptor — “intercepts” or “captures” grease, preventing it from entering the sewer system and causing clogs, backups and overflows that can halt business operations and harm the environment.

Grease traps/interceptors come in a variety of sizes, with smaller versions designed to connect individual sinks and larger ones installed to service entire facilities. The type you need depends on the size of your establishment, the volume of food production and the space available for installation.

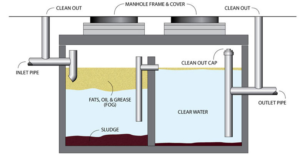

All types of grease traps/interceptors are designed to keep fatty waste (FOG) and water separated. They do this by using baffle walls that extend the length of the receptacle and increase the time and space for separation to occur. Eventually, the FOG will separate from the wastewater and flow out through the outlet fitting into the sanitary sewer system or septic tank.

Most municipal sewer systems have specific rules about the size and amount of FOG allowed to enter the waste stream. A properly sized and maintained grease trap/interceptor can help you avoid fines from your local wastewater authority for violating these rules by limiting the amount of fats, oils and grease that reach the sewer pipes.

Ideally, you want to have your grease trap emptied/pumped out every 1-3 months. A reputable company that services grease traps can work with you to create a scheduling plan compliant with these regulations.

In addition to having your grease trap emptied/pumped regularly, you can minimize the amount of FOG that ends up in your drains by educating employees on proper waste management. This includes using drain covers in kitchens, scraping food into trash cans instead of the sink and rinsing dishes with hot water rather than cold.

A grease trap is a vital part of any commercial kitchen, but it can also be a headache if you don’t maintain it properly. A clogged or overflowing grease trap can lead to costly repairs and delays in your business operations. By learning the basics of a grease trap and how they work, you can make the best decision about which one to purchase for your business.

How Does a Grease Trap Work?

FOG (fats, oils and grease) from kitchen sink drains can quickly build up to the point where it creates a serious clog. Without a proper grease trap to catch it, the FOG will continue flowing into the sewer system, leading to costly backups in your restaurant or sewage overflow into the community’s water supply.

Fortunately, a grease interceptor can prevent this from happening. Grease traps are a large, special receptacle that kitchen wastewater flows through before it enters the sewer waste system. Technically known as grease interceptors, they are an essential piece of plumbing for any commercial kitchen.

The trap is a large metal box with inlet and outlet pipes attached to it. As the kitchen’s wastewater flows through the trap, it slows down and becomes separated from the rest of the wastewater through a series of baffles. The separated grease rises to the top of the trap, while the solids settle at the bottom and the clear water escapes through an outlet baffle.

There are several different types of grease traps, but all of them work the same way. Some are larger and designed for restaurants, while others are smaller and meant for home and commercial use. The type of trap you choose will depend on your kitchen size and local regulations, if any.

A gravity grease trap is the most common and recommended for restaurants, but there are also automatic grease removal units that use a blade to separate the grease from the wastewater automatically, without any manual intervention.

The trap must be emptied regularly to avoid overflows and ensure that it remains compliant with all local regulations. Regular maintenance by a licensed grease trap service provider can help you stay on schedule and avoid costly clogs. A service provider will also educate your staff on handling food waste properly, using drain covers in kitchen sinks to catch debris and scraping foods off of plates into trash instead of the sink. They will also offer safe and environmentally responsible disposal of your trap’s contents, including processing used cooking oil and meat fats into animal feed, food-safe lubricants and renewable biofuel when available.

Grease Trap Installation

FOG (fats, oils and grease) buildup can cause clogs and backups that can stop the flow of wastewater in your restaurant. This can lead to serious plumbing issues and a restaurant shutdown. Moreover, these problems can also create a health and safety hazard for your staff and customers. Hence, it is crucial to have a grease trap or interceptor installed in your restaurant to avoid these costly and embarrassing problems.

Grease interceptors and traps are designed to prevent the accumulation of FOG in kitchen drains. These devices work as a filter by blocking the flow of FOG while allowing wastewater to pass through. This way, the waste is separated from the food scraps that can easily clog kitchen drains. In addition, these units help prevent the discharge of FOG into public sewer lines. This, in turn, limits water pollution and protects wastewater treatment plants.

The process of installing a grease trap involves selecting the right size and type of equipment for your establishment. You need to consider the drain size and the space available for the installation as well as any local regulations, if any. Once you have selected the ideal grease trap, it is then necessary to have it professionally installed. This process involves making the correct connections and ensuring that all kitchen drains run into the trap.

After the installation is complete, you must maintain your grease trap to ensure that it continues working effectively. You should have your trap examined on a regular basis by a service provider who can inform you of any visible damage or wear. In addition, it is important to have your trap cleaned regularly to avoid costly clogs, backups and overflows that can result from the accumulation of grease.

Keeping your trap clean will also reduce the amount of brown grease that is hauled away with your wastewater. This is a byproduct of the decomposition of food scraps in the trap and can be a health hazard for your staff, customers and the public. The most effective way to limit the production of brown grease is to have a separate food waste disposal system.

Grease Trap Maintenance

Grease traps must be emptied on a regular basis to prevent build-up of FOG, which can cause blockages in your drain lines. Professionals can handle this task for you and help ensure that your business is up to code. They will also make sure that the grease is disposed of properly to protect the environment and your business.

Cleaning the grease trap regularly prevents a host of problems, including foul odors, sinks that don’t drain and even grease build-up that can reach the sewer line and create major blockages called fatbergs that can span entire city blocks. By keeping up with your grease trap maintenance schedule, you can avoid these costly and time-consuming issues.

During the pumping process, technicians remove all of the hardened fats, oils and greases from your device. They use high-endurance pumps that safely and effectively remove the debris from your device, taking it to a large-capacity tank where it’s stored until it’s taken to a recycling facility for processing.

Professionals will also inspect the trap for any technical problems, such as broken filters, dents or walls. They can then repair these issues before they become more serious. In addition, they will use special scraping tools to clean all surfaces of the trap, ensuring that no trace of FOG is left behind.

Many commercial kitchens try to save money by attempting to clean the grease trap themselves, but this can be dangerous and lead to costly consequences. Pouring enzymes or chemicals down the drain to “clean” a trap actually just breaks down the FOG into smaller pieces that can be more easily dissolved in water and can then enter your plumbing system. In addition, some products may be illegal to use in your area or can cause the trap to clog or break down.

Performing regular grease trap maintenance by hiring a professional company like Mahoney Environmental is the best way to ensure that your restaurant’s grease trap is working as it should. In addition to preventing costly overflows, clogs and floods, these experts can also help you keep up with your regulatory compliance requirements and take the hassle out of grease trap maintenance.